Frequently Asked Questions

What You Need To Know About Grease Traps In Ireland

Grease traps are designed to reduce the amount of oils, fats and greases (FOGs) that get into the main sewers. Grease can build up in the central sewer system and cause blockages, foul odours, and pest infestations. Grease traps were first used in Victorian times. They are simply boxes placed within the wastewater drain from kitchen sinks to the foul sewer system. Grease traps are only designed to collect kitchen wastewater and should not be used for wastewater from other sources like the toilet.

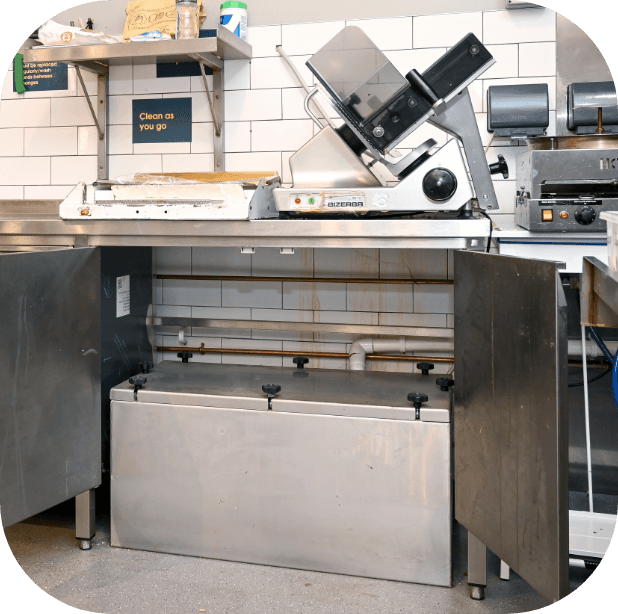

Grease traps can be made from various materials, including stainless steel, and mild steel. The most effective commercial models must be sized in accordance with IS EN 1825 (part 1 and 2). Regular food vendors and food shops usually require up to 200 litres, but this depends on the size of their kitchen and their FOG output.

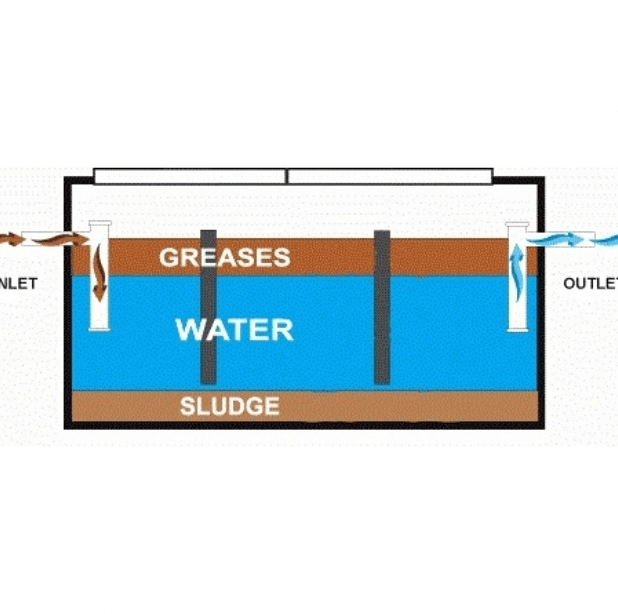

Grease traps are based on the principle that FOGs float in water and solid particles sink. The trap’s baffles slow down the inflow of wastewater. This allows the unit to settle and separate oils, water, and food particles. FOGs are prevented from flowing through the outlet by a trap and retained in the unit, along with food particles. This allows for cleaner water to flow through. Regular servicing is required to remove the waste and keep it from building up.

Irish Water requires that all new constructions and renovations of hot food establishments must have the means to remove grease from the site. These are necessary at all hot food preparation sites for the staff or the public. These sites include but are not limited to:

• Restaurants.

• Hotels.

• Colleges and Schools.

• Takeaways.

• Inns and Pubs that prepare food on-site.

• Canteens at factories or offices.

• Cafes.

• Bakeries.

If your business discharges trade effluent into a public sewer, you’ll need a trade effluent discharge to sewer license (issued under Section 16) of the Local Government (Water Pollution) Act 1977 as amended) will be required. Restaurants, takeaways, pubs serving food prepared in-house, cafes, coffee shops and hotels all need a trade effluent discharge to sewer license. A Fats, Oils, and Grease (FOG) Trade Effluent license is required for all restaurants, takeaways, and other establishments that prepare food. A properly sized grease trap must be installed on the premises. This is determined by the amount of wastewater generated by the establishment. Irish Water will inspect it regularly and require that the grease trap be maintained, cleaned, and serviced regularly. Records are needed to prove this.

There are different-sized units available; the amount of wastewater determines your required size. One of our team will call to evaluate and decide which size grease trap is best suited for your business and whether it needs to be installed outdoors or indoors.

To comply with waste regulations, a food service establishment (FSE) must install grease trapping or grease retention equipment to reduce fat, oil, and grease (FOG) levels in the final discharge. Best Management Practices (BMP) must also be implemented within an FSE to minimise FOG production. The design, operation and maintenance of grease management equipment must be fully per the relevant standards and the manufacturer’s instructions. Undersized or oversized equipment will not produce the required results.

Grease traps require regular cleaning, and the recovered FOG/water mixture must be collected by a properly licensed waste contractor and disposed of at a licensed facility. In addition, we provide complete maintenance services so you can rest assured that your business is looked after correctly and to all the correct standards.

The minimum cleaning frequency required for grease traps/interceptors is 90 days for good maintenance of your grease traps. However, more frequent cleaning intervals are recommended to prevent grease traps/interceptors from operating poorly or improperly. Some other best management practices we suggest you follow include the following:

• Regular inspection and maintenance of the grease management system

• Develop a grease trap/interceptor cleaning procedure and maintenance log /record for staff.

• The use of strainers in sinks.

• Dry wiping and/or pre-rinsing dishes and pots before they are washed to remove additional grease.

• Before cleaning, allow ice to melt in the sink; this will reduce odours and cause grease to congeal, making removal easier.

• Remove only grease and any accumulations and leave the water behind.

• Flush with warm soapy water after a clean-out and a final visual inspection.

Grease Traps should be fitted between the source of grease and your sewer system. They are available as indoor or outdoor models and can be sunk in the ground or floor mounted, with a choice of covers to suit all types of flooring materials and load-bearing requirements.

When inspectors visit your business from Irish Water, and you don’t have a grease trap fitted in your kitchen or you have a malfunctioning grease trap. If this happens, the inspectors will usually advise you to contact a licenced company (BIO GREASE Solutions Ltd) to rectify the situation. However if this is a regular occurrence other actions may be taken.

Any liquid waste discharged from business premises to the public sewers is called trade effluent. Businesses must have a Trade Effluent Licence to discharge trade effluent into the sewer.

Irish Water and the EPA regulate trade effluents that are discharged to the sewer. To discharge trade effluent into the sewer, you must have a licence for trade effluent or an EPA license. The regulatory authority that licences trade effluent to be discharged into the sewer will depend on the type and extent of the activity.

A Trade Effluent Licence sets out conditions that businesses must comply with. These may include: The nature, composition and volume of the trade effluent discharge the method of treatment, the location of discharge and the periods during which discharge may be made the taking and analysis of trade effluent samples and the trade effluent records that must be kept Applicable charges for discharging trade effluent, as approved by the Commission for Regulation of Utilities (CRU) – Irish Water.

Uisce Éireann (formerly Irish Water) inspectors require licensees to maintain, document and monitor the performance of grease traps on their premises. If licenses fail to procure any of the above documents, they will be tagged as non-compliance licensees.

The Uisce Éireann inspector will notify you about any non-compliant issues with your grease trap. These issues should be addressed within the inspection period. Bio Grease Solutions Ltd can assist you with non-compliance issues; give us a call.

For each inspection, keep the following information:

1. A copy of the grease trap sizing calculation.

2. Design details showing volumes, flow rates etc.

3. Dates and times for all maintenance records.

4. Waste disposal records from a licensed contractor.

5. A copy of the current Trade Effluent FOG Licence.